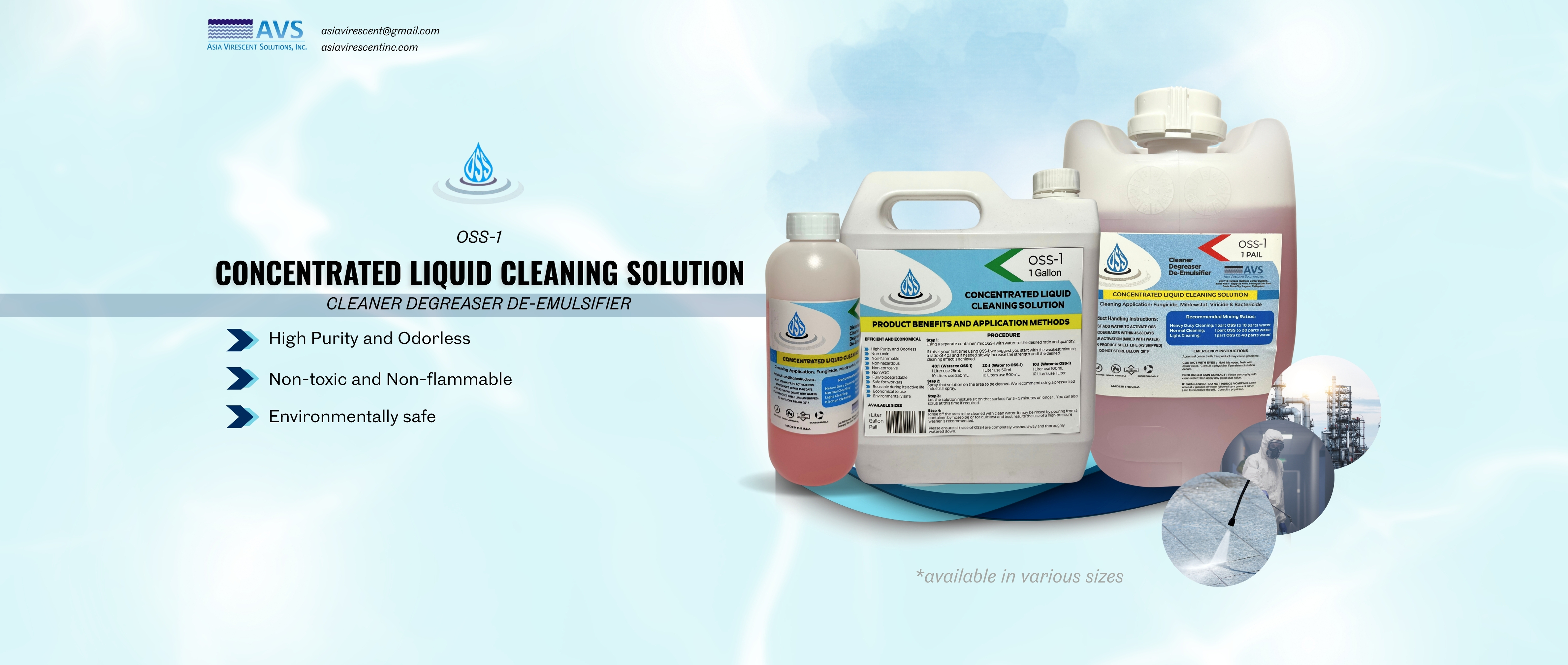

Comprehensive General & Industrial Cleaning Solutions:

OSS Multi-Purpose Cleaner

Introducing OSS MPC

OSS MPC is a water-activated concentrate designed to clean metal and plastic surfaces, effectively removing oil, grease, and organic contaminants. It excels in separating emulsified oil from water, making it ideal for industrial and maritime cleaning.

Key Advantages

-

Heavy-Duty Cleaning

Efficiently separates oil, water, and sediment.

-

Eco-Friendly Alternative

Replaces hazardous chemicals with a safer solution.

-

Non-Flammable & Non-Corrosive

Enhances workplace safety while maintaining superior cleaning performance.

-

Reusable & Cost-Effective

Enables oil recovery and extends equipment lifespan.

Applications

Maritime Cleaning

- Cleans grease traps, septic tanks, and oil-water separator systems.

- Safe fuel tank cleaner and effective oil/grease remover from equipment, exhaust systems, and disposal areas.

- Ideal for vehicle, truck, and cargo hold cleaning.

- Removes baked-on oil and grease from exhaust hoods and fans.

- Works with both freshwater and saltwater.

General Cleaning

- Non-Toxic & Biodegradable: Suitable for schools and food processing facilities.

- Reusable & Cost-Saving: Sustainable cleaning solution.

- Corrosion Inhibitor: Removes and prevents corrosion for extended equipment life.

- Versatile & Eco-Friendly: Applicable across industrial, maritime, and environmental settings.

Environmental Benefits

OSS serves as a degreaser, de-oiler, soil wash, PCB removal agent, and non-corrosive industrial cleaner while improving product recovery efficiency. It enhances hydrocarbon phase separation, recovering 1-20 barrels of oil per 1,000 gallons of OSS-water solution.

Competitive Edge

- Superior Performance: Outperforms competing products in effectiveness and usability.

- Safer Alternative: Prevents contamination, unlike solvent-based cleaners.

- Cost-Effective Dilution: Requires a 1:20 ratio for heavy deposits and 1:40 for light contaminants, making it highly efficient.

Why Choose OSS?

✅ Affordable & Accessible – Cost-effective cleaning solution.

✅Safe & Sustainable – Improves workplace safety and environmental impact.

✅ Trusted & Effective – Proven performance across industries.

OSS delivers a comprehensive, high-performance cleaning solution while promoting sustainability and operational efficiency.

Let's collaborate for long-term benefits!

INDUSTRIAL AND INSTITUTIONAL

DEGREASING PARTS

Ideally suited for cleaning protective coatings and grease and grime off of new or used parts. OSS works in parts washing devices without modifications of the equipment and leaves no residue after drying. Oils and greases are forced to float to the surface of the cleaning solution and can be skimmed off for recovery and recycling. Remaining precipitated solids are cleaned of hydrocarbons

GENERAL CLEANING

Effectively removes oils, greases, and accompanying dirt from most surfaces. Can be applied mopping, with floor cleaning machines, or with low or high-pressure spray. OSS is also an effective internal cleaner of hydraulic and lubrication systems, removing hydrocarbon and corrosive build-ups

Painting and Paint Preparation

OSS is an excellent choice for cleaning ferrous metal parts to be painted later.

After removing

oils and grease from parts, flash rusting while drying is prevented by OSS leaving an invisible barrier that provides extended corrosion protection. This barrIer can be painted over without additional rinsing.

Superior paint adhesion is obtained by cleaning parts in a OSS solution. Methods of cleaning vary between hand application, heated dip tanks, or pressure washing.

OSS is also an excellent choice for cleaning prior to powder coating parts.

WASTE TREATMENT SYSTEMS

Effectively separates oil, water, and solids in conveyer traps and floor sumps. Cleaned metal dust, shavings and dirt are precipitated to the bottom, the solution of OSS and water forms a barrier in the middle, and hydrocarbons are forced to float on the top. The efficiency of oil/water separators in plant waste treatment systems are significantly increased. The amount of toxic waste requiring disposal after treatment is also reduced. The solution of OSS and water can be reused to treat more waste materials until biodegradation occurs and it no longer effectively forces oil and water to separate

MARITIME AND PETROLEUM

General Cleaning

Cleans oil, grease, carbon deposits, and dirt in engine rooms and cargo holds, on bulkheads and decks, and in crew living and duty quarters. Lifts and removes oil and grease that has been baked on to hot engine parts, steam lines, etc. An ideal non- corrosive cleaner for reusable filters in engine oil and lubrication systems. Salt water as well as fresh water can be used to activate OSS

WELL TREATMENT

When injected into wells, OSS maintains the crude in a fluid state even at reduced temperatures and pressures following treatment. It also relieves clogs due to drilling mud accumulation. Does not physically or chemically alter the crude oil. Will increase flow rates by migrating into the oil-bearing strata and lifting crude oil trapped in the pores of the rock or sedimentary formation. Does not add to hazardous waste disposal problems.

Oil and Water Separation

Increases the effectiveness of oil/water separation systems and extends the life of disposable filters. Completely separates oil from oil/water emulsions in the bilge. Solids in bilge (both settled and suspended) will be cleaned of hydrocarbon contamination and suspended solids will be precipitated to the bottom of the bilge. Salt water as well as fresh water can be used to activate OSS

PIPELINE FLOW ENHANCER

Does NOT allow oil and water to mix and maintain crude oils in a liquid state, even at reduced temperatures. Keeps lines and pumps cleaner, boosting flow and cutting maintenance costs. Causes entrained water and inorganic solids to separate from the crude oil, providing a higher-grade product at the refinery/terminal

Cleaning Oil and Sludge Storage Tanks/Pits

Cleans tank walls using normal spray cleaning equipment and does not alter the composition of the recovered product.

The chemical process separates sludge into three components:

• Cleaned precipitated solids with low toxicity on the bottom

• A barrier solution of water and the OSS product compose the middle layer

• Separated oil on the top layer that can be recovered and recycled.

This process does not create explosive gases or caustic fumes or mist. Final bacterial remediation

can be speed up by a factor of 10 or more

Soil Remediation

Removes more than 95 percent of the hydrocarbons from contaminated soils in the first-stage process. Recovered oils may be recycled

Water component requires little, if any, predisposal processing. Total time required for complete remediation is reduced from years to weeks

ODOR CONTROL

- OSS products can eliminate most odor problems in water systems due to bacteria and other organisms. The odor is eliminated at its source and not masked or covered up

- OSS works in a different way than products containing a masking fragrance or enzyme products which tend to be very expensive, slow, and less than ideal in terms of effectiveness. Odor control is also achieved in many other applications where cleaning is performed on food processing equipment or containers, sewage treatment plants, and other waste water treatment facilities

- OSS is able to break down organic compounds that are responsible for releasing VOC’s that are associated with various odors in commercial and industrial systems

- OSS actually eliminates bacteria odor-generating capability by disrupting their cell wall integrity and function... Microorganism cell walls are made up of organic material including lipids (fats). The alkalinity and surface active ingredients of the formula breaks down the organic cell walls which protect the internal workings of the bacteria. Once the integrity of the wall is compromised bacteria can no longer absorb nutrients and eliminate waste. This kills the organism which no longer has the ability to generate VOC’s ( noxious odors

- OSS has tremendous advantages over toxic or enzyme based oil/odor control products that only mask the odors. Enzyme based formulas are slow to work and require maintenance to keep the enzymes active. Masking agents are mostly ineffective and expensive

- OSS will eliminate once and for all the odors and smells associated with organic material including bacteria and other organisms

OSS LABORATORY ANALYSIS AND EVALUATION RESULTS

PIPAC

PIPAC Analysis of OSS-1 Multipurpose Cleaner & Degreaser

UP NSRI

Bio-Assay Test Result for OSS Multi-Purpose Cleaner

Customer Evaluation

Kitchen Hood Cleaning using OSS-1

Food Industry

Product evaluation of OSS-1 to the Food Industry

Coolmate Corp.

ON SITE PRODUCT DEMO USING OSS

Picasso Hotel

ON SITE PRODUCT DEMO USING OSS

Carpet Cleaning

ON SITE PRODUCT DEMO USING OSS ON INK STAINS

Aircon Cleaning

Using OSS - Evaporator/Spot Cooler

EPSON

Using OSS-1 Multi-Purpose Cleaner/Degreaser

Heavy Equipment

Using OSS Multi-Purpose Cleaner

Industrial Cleaning

Barrel Lid and Drum Cleaning Using OSS

Charger AirCooler

Charger Air Cooler cleaned with OSS

Crankshaft Oil Pan

Using OSS-1 Multi-Purpose Cleaner/Degreaser

Piston

Evaluation Report using Green Power

Car Parts

Cleaning using Green Power